A UNIQUE PROCESS

Choose a robust, one-piece concrete solution

When you choose a one-piece concrete pool, you are choosing a guaranteed water seal and a truly reliable product.

With MARINAL SYSTEM, galvanised steel panels are assembled to provide a continuous formwork structure to your traditional reinforced concrete pool.

Thanks to the continuous steel reinforcement, concrete can be poured in a single phase for both the sides and the floor. This allows the concrete to set evenly, as a single block, while the steel formwork remains in place. The steel acts as reinforcement, strengthening the structure of the pool.

Even better, the concrete has no joints or connections, and is of a uniform density.

This means that MARINAL pools made from reinforced, one-piece concrete have no weak points, and there is no risk that the seal will be compromised.

One-piece concrete construction offers the greatest reliability in terms of robustness and longevity for a pool.

Any shape, any size

Thanks to the one-piece construction technique, any size and shape of pool is within reach.

MARINAL SYSTEM offers pools in both traditional shapes and free-form or contemporary designs, plus lap pools, infinity pools, mirror pools and even above-ground or partially raised pools.

Compatible with every type of surface

Similarly, pools built with the MARINAL SYSTEM technique can handle any type of finish (reinforced membrane, liner, tiling, mosaic, primer and more).

Are you looking to build a traditional pool? Get in touch with your approved MARINAL SYSTEM pool installer using our contact form.

DISCOVER HOW MARINAL SYSTEM POOLS ARE BUILT IN PICTURES

DISCOVER HOW MARINAL SYSTEM POOLS ARE BUILT IN PICTURES

DISCOVER HOW MARINAL SYSTEM POOLS ARE BUILT IN PICTURES

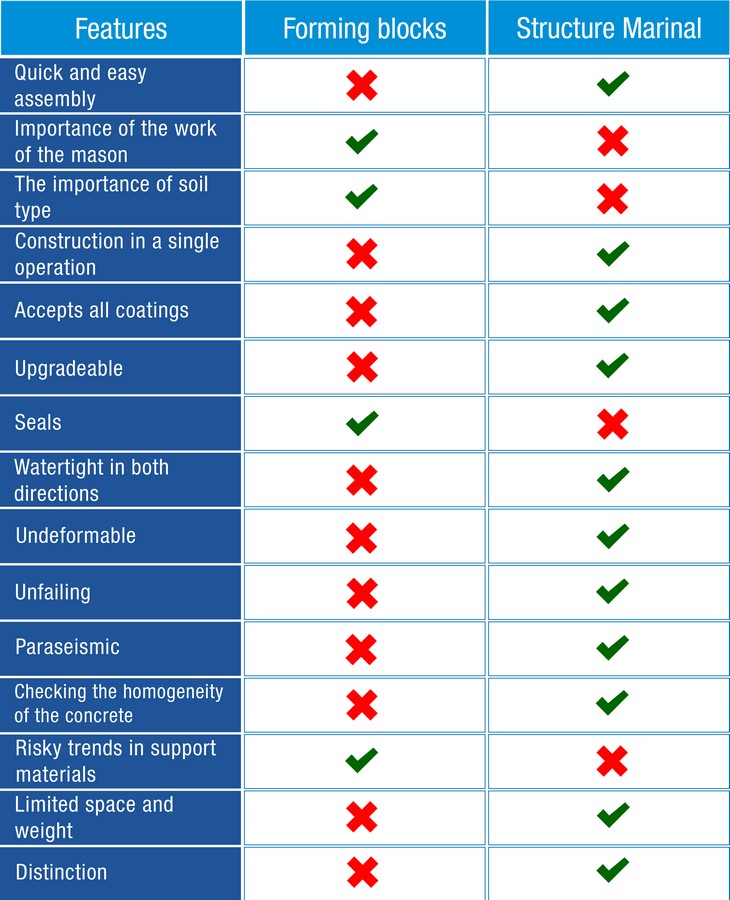

THE DIFFERENCES BETWEEN SHUTTERED CONCRETE, BREEZE BLOCKS AND POOL BLOCKS

Important: don’t confuse a pool built from one-piece lined concrete with one made from breeze blocks or pool blocks.

The techniques are very different, and will not give you the same quality pool.

MARINAL SYSTEM builds pools using reinforced concrete with integrated structural formwork, which strengthens the concrete and allows all the concrete to be poured into the galvanised steel in one go. This guarantees that your structure will never crack and never deform.

Breeze block and pool block techniques are modular, using joints

The MARINAL SYSTEM technique is a one-piece, continuous concrete solution.

THE RISKS OF USING POOL AND BREEZE BLOCKS

- The structure is at risk of deformation from the force of the water within and the terrain around the pool.

- Cracks can form and water can penetrate from the outside. Breeze and pool blocks offer no water seal guarantee.

- Bacteria and mould can grow between breeze blocks and the liner.

- Breeze blocks will crumble after the liner pulls away.

- This does not offer long-term reliability.

ADVANTAGES OF ONE-PIECE LINED CONCRETE

- No joints = no risk of losing your seal

- The concrete can be poured perfectly evenly

- The concrete is properly compacted = ensuring robustness and a good seal

- Adapts to all types of terrain, including seismic zones.

- Can be used as shoring.

A HEART OF STEEL AND A BODY OF CONCRETE

ONE-PIECE CONCRETE

The MARINAL SYSTEM technique uses a structured galvanised steel formwork system.

The panels consist of 2 metal mesh panels, reinforced with vertical stiffeners which also act as an anti-cracking mesh.

The panels are fixed to each other to form a structure and give a clear image of how the concrete will be poured.

The concrete is poured into the formwork (which remains an integral part of the pool, reinforcing the concrete).

The walls and base slab of the pool are poured at the same time, promoting concrete cohesion and forming a pool made of a single piece of concrete.

The seals between the parts are all embedded in the concrete.

KEY POINTS

- Integrated structural formwork

- A one-piece structure

- Will not deform, will not crack

- Visual pouring check

- Free-standing

- Compatible with every type of surface

- Customisable

- A patented construction process